When we talk about fabric, few people will notice the complicated craftsmanship hidden behind it. However, "high-temperature dyeing" is an amazing technological innovation, which brings unique fabrics with bright colors and consistent textures. Today, we will uncover this mystery together.

From traditional to modern: the development of high temperature dyeing technology

The history of textiles runs through almost the entire history of human civilization, and dyeing is an indispensable part of it. Early hand dyeing, although full of charm, but it is difficult to ensure the consistency of large-scale production. With the progress of science and technology, people invented "high temperature dyeing", which fixes pigment molecules by precisely controlling temperature and time, so as to achieve a more lasting color adhesion effect.

The Art of Color: Why High-Temperature Dyeing Can Make Colors So Vivid

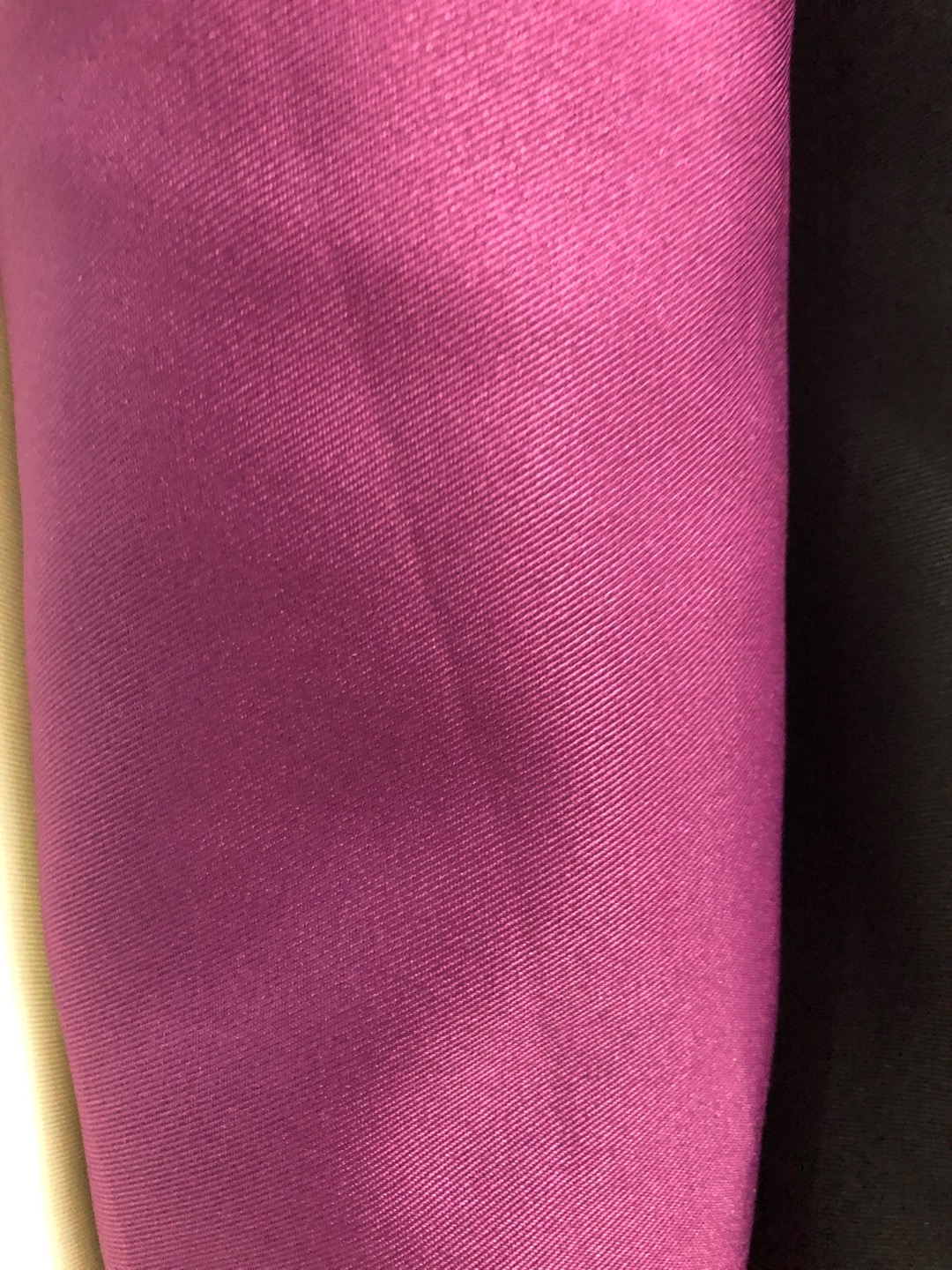

Different from ordinary low-temperature treatment, the chemical reaction in high-temperature environment is more thorough, so that each pigment can be deeply embedded in the fiber instead of just staying on the surface. This means that the original bright color can be retained even after repeated washing. Not only that, because of the higher degree of penetration, so the overall presentation of the visual level is also more rich and full.

The Secret of Plain: How to Achieve the Double Unity of Touch and View

In addition to the conspicuous colors, another highlight is the so-called "plain". This means that there are no obvious concave-convex marks or messy arrangement on the surface of the fabric, giving a clean first impression. In order to achieve this standard, manufacturers must use special weaving techniques and strict quality inspection procedures to ensure that every inch of the finished product meets the expected requirements.

Quality Assurance: Exploring the Stability of High Temperature Dyeing Fabrics

high quality is never an accidental result, but a reward that depends on a series of scientific management measures. For example, the whole process monitoring mechanism will be implemented throughout the processing process; in addition, there are research projects specifically aimed at fading problems, and so on. All these efforts eventually converge into a product that can stand the test-neither easily deformed nor lost its original luster.

Widely used: what occasions and clothing types are suitable for

Because of the many advantages mentioned above, these new materials are very suitable for the clothing production process in various formal or casual scenes. For example, business suit need to reflect the professional image is inseparable from their support; and for outdoor sports enthusiasts, you can further strengthen the practical function through the waterproof coating.

The behind-the-scenes story: the high-tech content behind a piece of clothing

maybe when you put on a new dress, you don't realize how much wisdom it contains? in fact, just a few seemingly simple processes may involve the work of dozens of engineers working day and night! And considering environmental protection factors, more companies are now actively exploring solutions for green and sustainable development ~

Future Trends: Where will high-temperature dyeing technology lead the industry?

Looking to the future, we can foresee that this mature and innovative technology will continue to promote the upgrading of the global garment industry. At the same time, with the increasing popularity of personalized customized services, I believe that more and more brilliant works will appear in front of the world and wait to be discovered and appreciated!